The chronological milestones for late finishing stand roll grade families at Union Electric Åkers are the ICDP, Enhanced ICDP, and the newest, TwinAlloy™ Steel.

The IC rolls in the early stages of research and development were based on the former design of Ni-hardened material, where a high volume of cementite was generated within the matrix to reach greater hardness and increased wear resistance when compared with white iron.

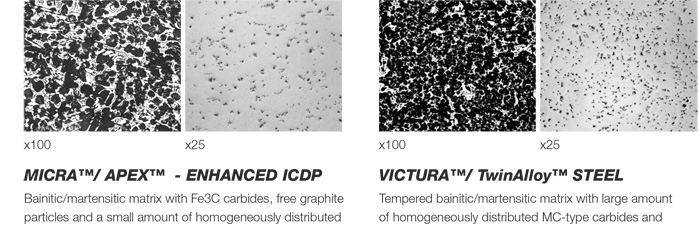

The MC-type of carbide was first introduced into Enhanced ICDP rolls to improve performance. With the most recent development of VICTURA™ TwinAlloy Steel, Union Electric Åkers introduced additional MC-type of carbide as well as other carbides to achieve an optimized balance of cementite, MC-type carbides, and graphite which resulted in a homogeneous distribution of all phases. By incorporating this concept, a large number of elements that promote the formation of MC-type of carbides are used.

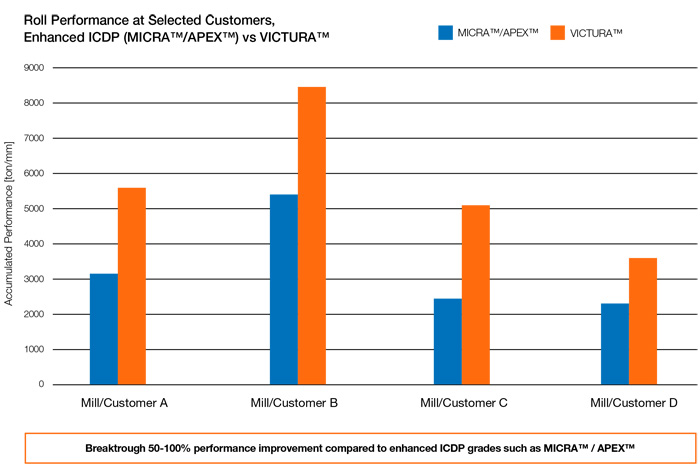

“Our key objective in the project was to develop a new R&D approach that would result in a major performance step change when compared to our existing grades used in late finishing stands. Throughout the prototype phase we have been able to show a consistent 50-100% performance improvement over Enhanced ICDP type of rolls,” says Jason Sychterz, Vice President of Technology at Union Electric Steel. “TwinAlloy material characteristics are primarily the combination of cast and forged alloy design philosophies, coupled with refined and modified process technologies. Looking ahead, we are further developing TwinAlloy technology and are in fact testing prototypes in a new TwinAlloyHSS grade with exciting results.”

“The TwinAlloy technology concept represents a series of forged and cast roll materials developed by Union Electric Åkers that aims to bring breakthrough improvements in performance and Total Cost of Ownership in both hot and cold rolling applications,” commented Stefan Wahlund, Director of Product Management and Marketing. “A critical aspect of our development and design of new TwinAlloy technology products is the ease of implementation for the customer. With our VICTURA grade, we have a true plug and play product.”

VICTURA TwinAlloy Steel is designed for hot rolling, late finishing stand application and combines the High Speed Steel SPECRA™ and enhanced ICDP MICRA™ / APEX™ technologies introducing even more MC-type of carbide. By adapting high alloy tool steel based carbides to an iron-based graphite morphology, the campaign lengths of early (HSS) and late finishing stands can be closely matched. The combination of MC carbides and the microstructure develops excellent oxidation characteristics which promote extended rolling campaigns.

Figures show the microstructural comparison between the Enhanced ICDP and the VICTURA TwinAlloy Steel material.